Related Posts

1 Mistakes Made

2 Worktop-to-Hood Distance

3 Dish Drainer Cabinet

4 What Will We Do Differently?

5 Kitchen - Mistakes

6 Plumbing - Sinks

After the cabinets and drawers were completed, we tested the drawer movement for a few days. We were particularly keen to test the load-bearing weight of the deep drawers, especially as drawers provide the main storage for the kitchen. Opening and closing countless times daily, the drawers have to be the workhorse of the kitchen.

Would the drawers stand up to daily punishing usage when fully loaded?

Would we encounter an issue opening and closing fully-laden drawers? Could they take the punishing weight day-in, day-out? After all, with each deep drawer measuring 29-inches wide and 14-inches high and extending fully, they are certainly huge. Fully laden, we felt it would not be easy to open and close the drawer.

Testing the Drawers

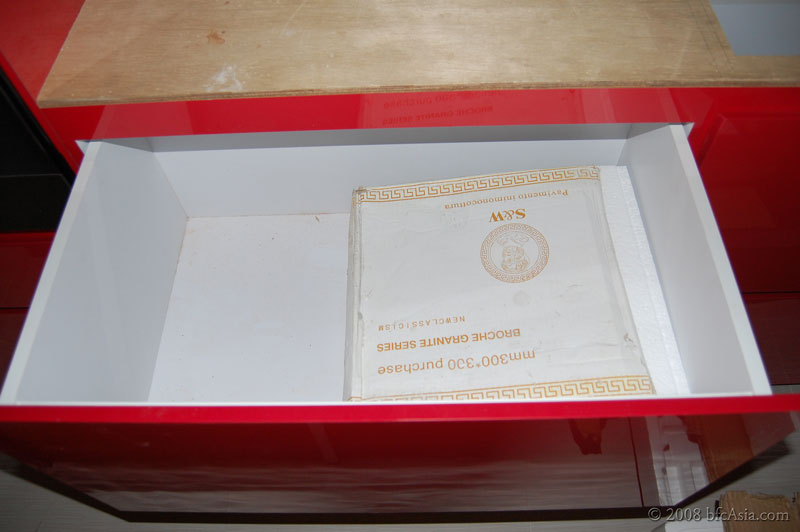

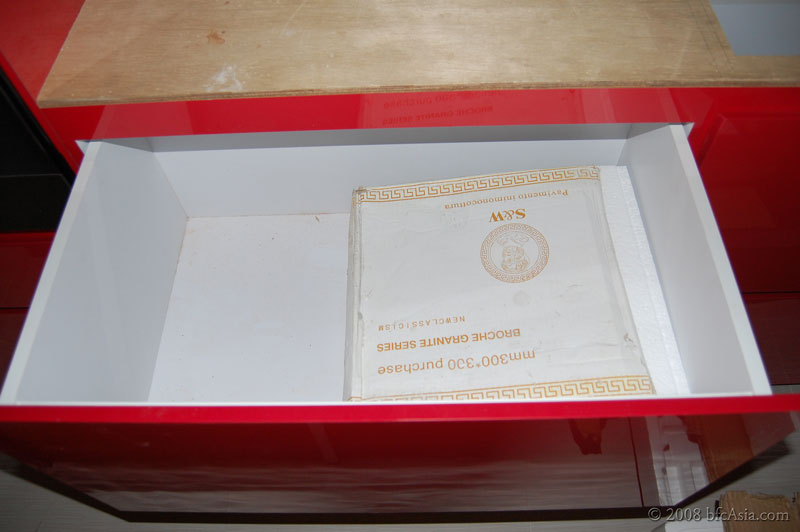

We loaded one carton of homogeneous tiles weighing 21 kg into the drawer, and tested the laden drawer. The drawer opened and closed beautifully. No hitches, nothing caught, no stickiness. Movements were quick and smooth.

Drawer loaded with 21-kg weight

We then added another carton of tiles to the one in the drawer, doubling the weight. Then we tested the drawer again. Wow, although the drawer was heavy, movement was still smooth, although not quite as quick as earlier. But the movement was smooth, and the soft-closing mechanism still worked, pulling the drawer shut towards the end.

Less-than-specified load rating for drawer runner slide

Mention must be made however, that we had specified 50kg load bearing for the Hettich runners when we first discussed the cabinet design with the ID. What was provided however was the Quadro model. No one had realized the Quadro was rated for a maximum load of only 30kg. We found that out later when we googled for the product info on the Quadro. Blame the ID mistake on ignorance in purchasing, or unfamiliarity with the various models available. Whatever the case, the redeeming feature of the Quadro was its hidden mounting feature. When the drawer opened, the Hettich runner was not visible as it was mounted on the drawer underside, hidden from view.

It is unlikely our huge drawer fully loaded with plates, bowls, and cutlery will weigh as much as 30 kg. So we didn't mind having the Quadro model as the drawer runner slide for the drawer system. Time will tell whether or not we made the right decision.

Missing drawer runner slide catch

We next tested each drawer for smooth operation and soft-closing. The drawers were opened and shut several times. All drawers opened and closed effortlessly and smoothly, with a soft-closing feature kicking in towards the end, "pulling" in the drawer completely into the base cabinet.

All except two, that is. Two drawers were found to "stick" occasionally.

Further investigations revealed that the two drawers had only one drawer runner slide catch or clip instead of two. One metal clip supporting the drawer runner slide was missing on the underside of the two drawers. Hence the drawer occasionally lurched when closing or opening.

Only one Hettich drawer runner slide catch was attached

Missing drawer slide catch installed

After the carpenter installed the missing drawer clips, the drawers opened and closed as smoothly and effortlessly as the other drawers.

Adjusting Shelf Height

A second mistake was in the depth of the drawers in the row directly beneath the cooker hob worktop.

After the drawers in the base cabinets were completed, we found we could not place bottles of condiment like vinegar or soy sauce in them. The bottles were taller than the inside of the drawers!

Apparently aesthetics had taken an upper hand. It was prettier to design two equal rows of drawers of the same height on the hob base cabinet. The alternative would be an upper row of deeper drawers to accommodate tall bottles and a lower row of shallower drawers.

Not a pretty arrangement, we agreed. This was one of those tradeoffs we accepted, where aesthetics won over functionality.

Fortunately it was not one of those do-or-die mistakes.

We could simply adjust the shelf higher in the wall cabinets to take the tall bottles.

Original shelf position

Instead of placing condiments and sauces like vinegar, soy sauce, peanut oil, shiao-xing wine, etc in the deep drawer beneath the cooker hob, we would place them in a tray-like rack and place the the rack on the lower shelf of the wall cabinet.

Shelf moved higher

We would only need to take the condiment rack down from the wall cabinet and place it conveniently on the worktop when we cook.

Doing this makes it easier and cleaner to access soy sauces, spices, shiao-xing wine, etc that we use for cooking. It also makes for a less cluttered worktop when the condiment rack is put away after cooking.

EDL laminate for kitchen cabinets

We first noticed a side of the oven cabinet had suffered abrasions and the plywood showed through the abrasion a day after the electrician had completed their work in the kitchen. Well, there was nothing we could do to rectify the abrasion, except maybe to apply red paint of a similar shade to the laminate to hide the exposed wood.

Side laminate of oven cabinet marred by abrasions

A few days later, the carpenter understudy was none too careful and lightly brushed the plastic padded heal of the aluminum ladder against the side of the sink cabinet as he moved the ladder into the bathroom. It was merely a light brush, because I was helping him to move the ladder.

On closer examination of the laminate after the contact, I was surprised to see the laminate was "bruised" by the plastic-padded heel. There were abrasion marks and the surface had some red paint rubbed off. I was dismayed. Other laminates I had previously encountered would not have shown abrasions from the ladder contact. And I had expected the EDL laminate to take daily "knocks" without showing any the worse for them.

Light brush by ladder plastic heel cause abrasions to laminate surface

So why does the locally produced EDL laminate possess such poor abrasion resistance? Surely the manufacturer has a responsibility to ensure its laminate could withstand normal knocks and abrasions that arose in daily use? The carpenter commented the EDL laminate coating appeared very thin to him. Shouldn't EDL have used a thicker coating for the laminate?

If the EDL laminate is made with such a thin coating on the surface layer, the laminate is obviously unable to withstand the rigors of daily use in a kitchen cabinet. It is unsuitable to use for kitchen cabinets.

Readers should therefore always test a laminate, whatever the brand may be, for abrasion resistance before they adopt it for their kitchen cabinets. If possible, get a written guarantee and check the top surface layer has coatings within tested specified thicknesses. If such minimum standards are not applicable locally, then use comparables from other countries that have adopted minimum standards for laminate thicknesses.

As for us, we have to live with the issue and take extra precaution to avoid contact with any hard object on the laminate surface. We hope EDL will come out with a better product, for their latest glossy range of laminates looks really nice. However, until that happens, we will stop recommending EDL laminate to readers for their cabinets.

To be continued...

- Adjusting the basin level

- Fixing the soap dispenser

- Making the shelving beneath the sink

1 Mistakes Made

2 Worktop-to-Hood Distance

3 Dish Drainer Cabinet

4 What Will We Do Differently?

5 Kitchen - Mistakes

6 Plumbing - Sinks

After the cabinets and drawers were completed, we tested the drawer movement for a few days. We were particularly keen to test the load-bearing weight of the deep drawers, especially as drawers provide the main storage for the kitchen. Opening and closing countless times daily, the drawers have to be the workhorse of the kitchen.

Would the drawers stand up to daily punishing usage when fully loaded?

Would we encounter an issue opening and closing fully-laden drawers? Could they take the punishing weight day-in, day-out? After all, with each deep drawer measuring 29-inches wide and 14-inches high and extending fully, they are certainly huge. Fully laden, we felt it would not be easy to open and close the drawer.

Testing the Drawers

We loaded one carton of homogeneous tiles weighing 21 kg into the drawer, and tested the laden drawer. The drawer opened and closed beautifully. No hitches, nothing caught, no stickiness. Movements were quick and smooth.

Drawer loaded with 21-kg weight

We then added another carton of tiles to the one in the drawer, doubling the weight. Then we tested the drawer again. Wow, although the drawer was heavy, movement was still smooth, although not quite as quick as earlier. But the movement was smooth, and the soft-closing mechanism still worked, pulling the drawer shut towards the end.

Less-than-specified load rating for drawer runner slide

Mention must be made however, that we had specified 50kg load bearing for the Hettich runners when we first discussed the cabinet design with the ID. What was provided however was the Quadro model. No one had realized the Quadro was rated for a maximum load of only 30kg. We found that out later when we googled for the product info on the Quadro. Blame the ID mistake on ignorance in purchasing, or unfamiliarity with the various models available. Whatever the case, the redeeming feature of the Quadro was its hidden mounting feature. When the drawer opened, the Hettich runner was not visible as it was mounted on the drawer underside, hidden from view.

It is unlikely our huge drawer fully loaded with plates, bowls, and cutlery will weigh as much as 30 kg. So we didn't mind having the Quadro model as the drawer runner slide for the drawer system. Time will tell whether or not we made the right decision.

Missing drawer runner slide catch

We next tested each drawer for smooth operation and soft-closing. The drawers were opened and shut several times. All drawers opened and closed effortlessly and smoothly, with a soft-closing feature kicking in towards the end, "pulling" in the drawer completely into the base cabinet.

All except two, that is. Two drawers were found to "stick" occasionally.

Further investigations revealed that the two drawers had only one drawer runner slide catch or clip instead of two. One metal clip supporting the drawer runner slide was missing on the underside of the two drawers. Hence the drawer occasionally lurched when closing or opening.

Only one Hettich drawer runner slide catch was attached

Missing drawer slide catch installed

After the carpenter installed the missing drawer clips, the drawers opened and closed as smoothly and effortlessly as the other drawers.

Adjusting Shelf Height

A second mistake was in the depth of the drawers in the row directly beneath the cooker hob worktop.

After the drawers in the base cabinets were completed, we found we could not place bottles of condiment like vinegar or soy sauce in them. The bottles were taller than the inside of the drawers!

Apparently aesthetics had taken an upper hand. It was prettier to design two equal rows of drawers of the same height on the hob base cabinet. The alternative would be an upper row of deeper drawers to accommodate tall bottles and a lower row of shallower drawers.

Not a pretty arrangement, we agreed. This was one of those tradeoffs we accepted, where aesthetics won over functionality.

Fortunately it was not one of those do-or-die mistakes.

We could simply adjust the shelf higher in the wall cabinets to take the tall bottles.

Original shelf position

Instead of placing condiments and sauces like vinegar, soy sauce, peanut oil, shiao-xing wine, etc in the deep drawer beneath the cooker hob, we would place them in a tray-like rack and place the the rack on the lower shelf of the wall cabinet.

Shelf moved higher

We would only need to take the condiment rack down from the wall cabinet and place it conveniently on the worktop when we cook.

Doing this makes it easier and cleaner to access soy sauces, spices, shiao-xing wine, etc that we use for cooking. It also makes for a less cluttered worktop when the condiment rack is put away after cooking.

EDL laminate for kitchen cabinets

We first noticed a side of the oven cabinet had suffered abrasions and the plywood showed through the abrasion a day after the electrician had completed their work in the kitchen. Well, there was nothing we could do to rectify the abrasion, except maybe to apply red paint of a similar shade to the laminate to hide the exposed wood.

Side laminate of oven cabinet marred by abrasions

A few days later, the carpenter understudy was none too careful and lightly brushed the plastic padded heal of the aluminum ladder against the side of the sink cabinet as he moved the ladder into the bathroom. It was merely a light brush, because I was helping him to move the ladder.

Light brush by ladder plastic heel cause abrasions to laminate surface

So why does the locally produced EDL laminate possess such poor abrasion resistance? Surely the manufacturer has a responsibility to ensure its laminate could withstand normal knocks and abrasions that arose in daily use? The carpenter commented the EDL laminate coating appeared very thin to him. Shouldn't EDL have used a thicker coating for the laminate?

If the EDL laminate is made with such a thin coating on the surface layer, the laminate is obviously unable to withstand the rigors of daily use in a kitchen cabinet. It is unsuitable to use for kitchen cabinets.

Readers should therefore always test a laminate, whatever the brand may be, for abrasion resistance before they adopt it for their kitchen cabinets. If possible, get a written guarantee and check the top surface layer has coatings within tested specified thicknesses. If such minimum standards are not applicable locally, then use comparables from other countries that have adopted minimum standards for laminate thicknesses.

As for us, we have to live with the issue and take extra precaution to avoid contact with any hard object on the laminate surface. We hope EDL will come out with a better product, for their latest glossy range of laminates looks really nice. However, until that happens, we will stop recommending EDL laminate to readers for their cabinets.

To be continued...

- Adjusting the basin level

- Fixing the soap dispenser

- Making the shelving beneath the sink

1 Mistakes Made

2 Worktop-to-Hood Distance

3 Dish Drainer Cabinet

4 What Will We Do Differently?

5 Kitchen - Mistakes

6 Plumbing - Sinks

1 comments:

Thank you for yr comment. Your comment will spur us to make the site more relevant and useful for our readers.

Post a Comment

Hi, thanks for your comments. While I will strive to answer all your queries please be patient as I am overwhelmed at work.

Thanks for your understanding,

GreenCoal